Ball mills are vital equipment used in various industries for grinding materials into fine powder. They are commonly used in the mining, cement, and chemical industries to grind materials such as minerals, ores, and chemicals.

Importance of Maintenance

Proper maintenance of ball mills is essential to ensure their efficient operation and longevity. Neglecting maintenance can lead to decreased productivity, increased downtime, and costly repairs. But the premise of having considerable maintenance is you find a reliable manufacturer, you can search on googlem, also you can click and learn about this Chinese manufacturer.

Maintenance Techniques

Regular maintenance tasks for ball mills include:

- Checking lubrication systems

- Inspecting wear parts such as liners and grinding media

- Tightening bolts and fasteners

- Cleaning and inspecting critical components

Troubleshooting Common Issues

Some common issues encountered with ball mills include:

- Excessive vibration

- Overheating of bearings

- Excessive wear of liners

- Low grinding efficiency

Vibration Analysis

Excessive vibration can indicate misalignment, loose components, or worn-out bearings. Performing vibration analysis regularly can help diagnose and address underlying issues.

Bearing Temperature Monitoring

Monitoring bearing temperatures can help detect overheating, which can lead to premature bearing failure. Regular lubrication and proper alignment can prevent overheating.

Liner Inspection

Inspecting liners for wear and damage is crucial for maintaining optimal grinding efficiency. Worn-out liners should be replaced promptly to prevent damage to the mill shell.

Optimizing Grinding Media

Choosing the right grinding media and maintaining the optimal media charge can improve grinding efficiency and reduce wear on mill components.

Applications of Ball Mills

Ball mills are used in various industries for a wide range of applications, including:

- Grinding of minerals and ores in mining operations

- Production of cement and other building materials

- Manufacture of chemicals and pigments

- Preparation of ceramic materials

- Processing of food and pharmaceuticals

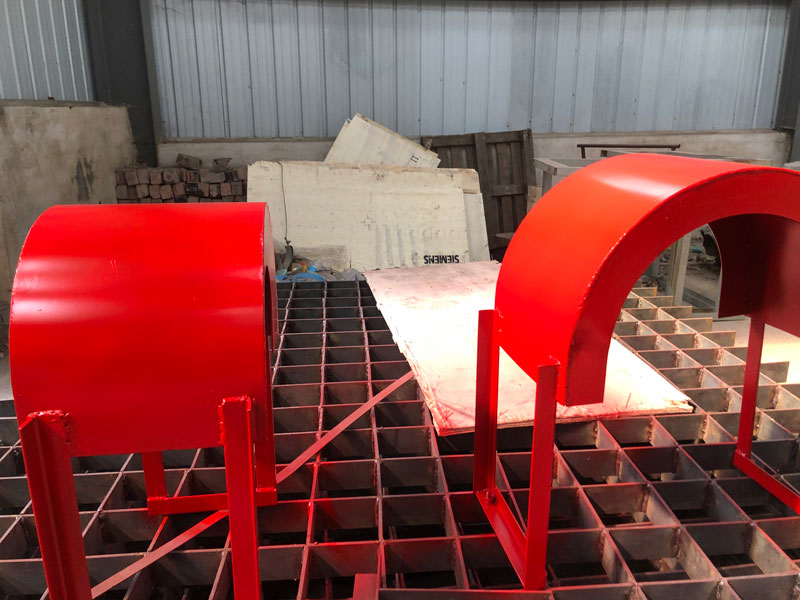

Raw Materials of Ball Mills

The raw materials used in the construction of ball mills include:

- Steel: For the construction of the mill shell, liners, and grinding media

- Alloyed steel: Often used for grinding media due to its hardness and wear resistance

- Rubber: Used for mill liners to reduce noise and vibration

- Ceramic: For manufacturing high-quality grinding media, particularly in specialized applications

Operation Guides of Ball Mills

Proper operation of ball mills involves several key steps:

- Start-up: Ensure all components are properly assembled and lubricated before starting the mill.

- Material Loading: Add the appropriate amount of material to the mill, taking care not to overload it.

- Running: Start the mill and monitor its operation, adjusting parameters such as speed and feed rate as needed.

- Monitoring: Regularly check the condition of critical components such as bearings, liners, and grinding media during operation.

- Shutdown: Properly shut down the mill by reducing speed and performing necessary maintenance tasks.

Connection to Crusher Plants

Ball mills are often used in conjunction with crusher plants in mineral processing operations. Various types of crusher plants, such as jaw crusher plants, cone crusher plants, and impact crusher plants, are employed to reduce the size of raw materials before they are fed into the ball mills for grinding.

Proper maintenance of both ball mills and crusher plants is essential for ensuring efficient operation and minimizing downtime in mineral processing operations.